Highly sensitive fiber optic pressure sensors for wind turbine applications

- Malik Kaya

- 29 Haz 2021

- 1 dakikada okunur

Fiber optic pressure sensors utilizing ultra-high sensitive fiber loop ringdown (FLRD) spectroscopy were fabricated using a bare single mode fiber. The fiber optic pressure sensors were applied to monitor pressure change on a plastic pipe embedded into a sea sand filled container in laboratory conditions to simulate a tower.

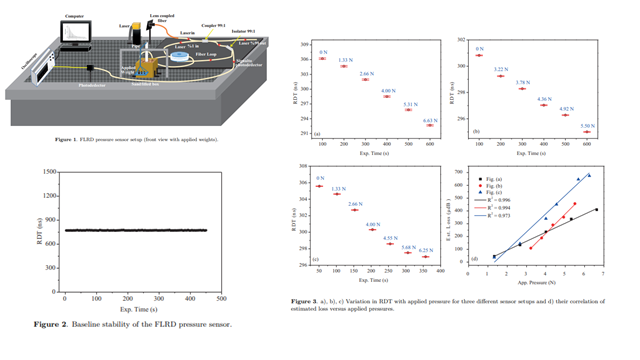

Fiber optic pressure sensors utilizing ultra-high sensitive fiber loop ringdown (FLRD) spectroscopy were fabricated using a bare single mode fiber. The fiber optic pressure sensors were applied to monitor pressure change on a plastic pipe embedded into a sea sand filled container in laboratory conditions to simulate a tower. As the pressure applied to the sensor head was changed from 66.4 kPa to 331.6 kPa, changes in the ringdown time (RDT) were recorded. The lowest baseline stability of 0.20 % was obtained in these simple FLRD pressure sensors. The minimum detectable optical loss was 992 μdB. The results showed that FLRD pressure sensors tested by applying to a pipe embedded into sea sand simulating a tower are highly sensitive and have high potential to be applicable for monitoring wind turbine components such as blades and towers in the sea or on land to determine the pressure on structures due to damage, excessive waves, or strong winds. The study also suggests that this type of FLRD pressure sensor can be utilized for the purpose of early detection in other important structures such as dams, buildings, and bridges.

Yorumlar